- Posted by: admin

- Category: Article

Lasercladding of ship propeller is a new coating technique, to provide shafts and rolls with wear and corrosion resistant alloys. According to the required functionality, dedicated types of alloy have been developed by TopClad. TopClad has recently developed TopBearing for propeller ship shaft bearings which is based on our Tardisphere coating.

About two years ago, TopClad introduced an alloy, in particular for the bearings of propeller and rudder shafts of ships. This dedicated alloy is very high wear resistant as well as high corrosion resistant. And it is a tough material that is not sensitive to fatigue, especially in case of misalignment.

TopClad laserclad technique can be applied on a wide range of shaft materials, carbon steel as well as stainless steel.

The excellent capabilities of this bearing material has been proven in practice on several ships. After 18 months, these propeller shaft bearings were 100% free of wear and corrosion. They still had the original shape and dimensions. In between, DNV witnessed and approved these lasercladded propeller shaft bearings.

In the past, a number of different bearing materials have been applied for propeller shaft. In the last years, HVOF coatings were popular (with or without carbides) as well as other ways of spray-on coatings. None of these coatings however, are sufficient corrosion resistant and not free from wear. As these types of bearing are not reliable, they lead to very high downtime costs of the vessel. TopClad laserclad is very reliable and sustainable in usage. It has a long lifespan and very low costs of ownership.

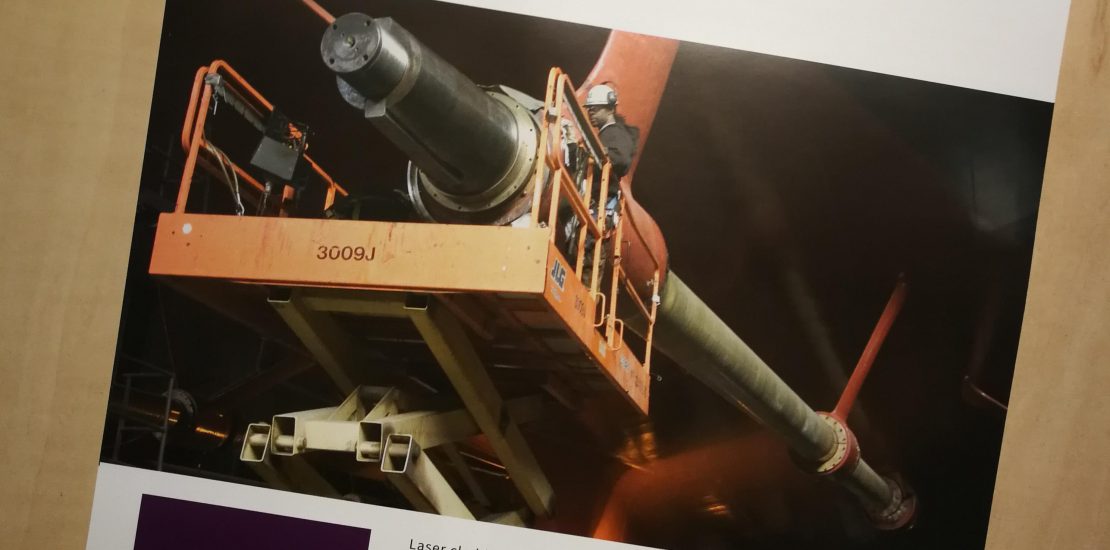

Lasercladding of ship propeller

Lasercladding is a process were a small melting pool on the shaft is created by a focussed laserbeam. At the same time, the selected alloy is added to the melting pool. In this way, the alloy is intermetallic attached to the shaft. After cooling down, the laserclad layer is stone grinded, to reduce the lasercladlayer to the required end specifications. The finished laserclad layer is standard about 200 – 250 um.

Because the laserbeam focusses on the surface of the shaft, and not deeper than that, the Heat Affected Zone will be very small. This will be not more than about 200 – 300 um. In this zone, the microstructure might have minor changes, basically recognized by some local increased hardness. Other physical properties like tensile strength, impact values and bending properties remain unchanged.

TopClad lasercladding has environmental advantages as well. Due to the focused laserenergy and related low heat input, just a small amount of electricity is needed, related to other coating processes. Next to that, there are no by-products, there is no waist and there are no chemicals involved

Functional and cost advantages.

- Topclad lasercladding has lots of technical and functional advantages related to bearing applications. The layer is 100% non-porous, in contrast to many other layers. The layer is full resistant to every way of corrosion.

- The welded bearing is intermetallic attached to the shaft. There is no way of delamination, like HVOF and galvanic coatings.

- The alloy that is selected for these shaft bearings is ductile as well as hard and wear resistant. That makes this type of bearing very useful in cases of misalignment and fluctuating shaftloads.

- Topclad lasercladding is a very effective repair and overhaul process. Worn-out and corroded spots from e.g. other types of coatings can easily being removes and build up with new laserclad alloys to the original shape and dimension and with better functional capabilities. Local damage e.g. due to external causes can easily being repaired “on-site”. Just a TIG welding machine is required. In this way, the cost of repair or overhaul and the leadtimes are very restricted.

The listed advantages of TopClad laserclad bearings make them very reliable for propulsion shafts. They have a long lifetime, low cost of maintenance and so low Cost of Ownership.

For more information please download our leaflet: TopBearing: Innovative ship propeller shaft bearings ; new and repairs