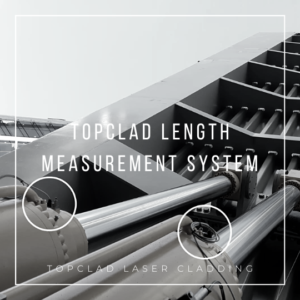

In the past Topclad used to apply galvanic nickel and chrome on hydraulic cylinders. Their knowhow gets back to over 40 years and has been very useful in the step to apply laser cladding layers as a substitute for galvanic nickel chrome. Topclad is able to remove existing galvanic chrome and HVOF layers and apply laser clad layers on rods from diameter 40 – 2200 mm with length up till 24.000mm. Topclad Length Measuring Systems can be included as well (also as substitute for Bosch Rexroth CIMS). And threaded ends on rods can be provided with nickel based thread, that makes it easy to screw and unscrew e.g. rod eyes after many years, without an resistance due to corrosion.

Wherever metal products need protection against corrosion, wear, heat or impact from outside, Topclad Laser Cladding offers high-quality solutions. The only prerequisite is that the product has a cylindrical shape like a rod, drum, roller, bearing or likewise. In the offshore market the demands on corrosion resistance and especially on pitting are high. In the dredging and mining industry the focus lays on impact, wear and corrosion resistance. Integrated length measuring systems, high corrosion resistance and high-quality surface roughness are important features for bridges and water locks. For the steel processing industry, the laser clad layer needs to be high wear and heat resistant up till 950 °C and high hygienic (sanitary) properties are important for the food processing industry.

Over the years Topclad Laser Cladding has developed a wide range of laser clad layers. Specially engineered alloys have been tested in cooperation with our customers, suppliers and notified bodies to meet a variety of customer needs.

TLMS is a length measuring system for hydraulic cylinders up to 24.000mm long. It is based on a sensor that recognizes small interrupted magnetic fields along the cylinder rod. These interrupted magnetic fields are positioned on fixed distances over the full length of the rod. At the moment that the cylinder rod moves along the sensor, the sensor will issue two pulses. First at the beginning of magnetic field and secondly at the end. The distance between two magnetic fields is kept the same over the full rod length.