Laser clad layer Tardisphere

Tardisphere is a high-performance laser clad layer engineered to deliver superior wear and corrosion resistance in extreme environments. Unlike traditional tungsten carbide coatings, Tardisphere combines very high hardness with ductility due to its metallurgical bond, providing unmatched durability.

Tardisphere, ideal for harsh conditions

Tardisphere is ideal for components exposed to harsh conditions such as mining and dredging. Its chemical resistance and ability to withstand mechanical stress make it a cutting-edge solution for industries that prioritize equipment lifetime and reliability, while also aiming to reduce total cost of ownership.

Benefits of Tardisphere

Tardisphere offers a range of advanced properties, making it a preferred choice for corrosive, high-stress, and abrasive environments. Key benefits include:

- Extreme wear and corrosion resistance

Engineered for environments where high wear and corrosion resistance are essential, Tardisphere excels in providing a long-lasting protective barrier. - Impact resistance

Specifically designed to withstand mechanical impacts from external sources like stones or debris, making it perfect for dredging, mining, and demolition equipment. - Suitable for both longitudinal and rotational movement

Tardisphere’s unique combination of high wear resistance and ductility ensures smooth performance in both linear and rotational applications. This makes it particularly effective for use in oil- or water-lubricated bearings, such as those found in ship propeller shafts, where consistent performance under variable loads and in corrosive environments is crucial. - Cost-effectiveness

Tardisphere’s durability significantly reduces maintenance and replacement needs, lowering the total cost of ownership over time. - Certified by Bureau Veritas

The certification by Bureau Veritas guarantees the quality and reliability of Tardisphere, making it an ideal choice for long-lasting, certified solutions..

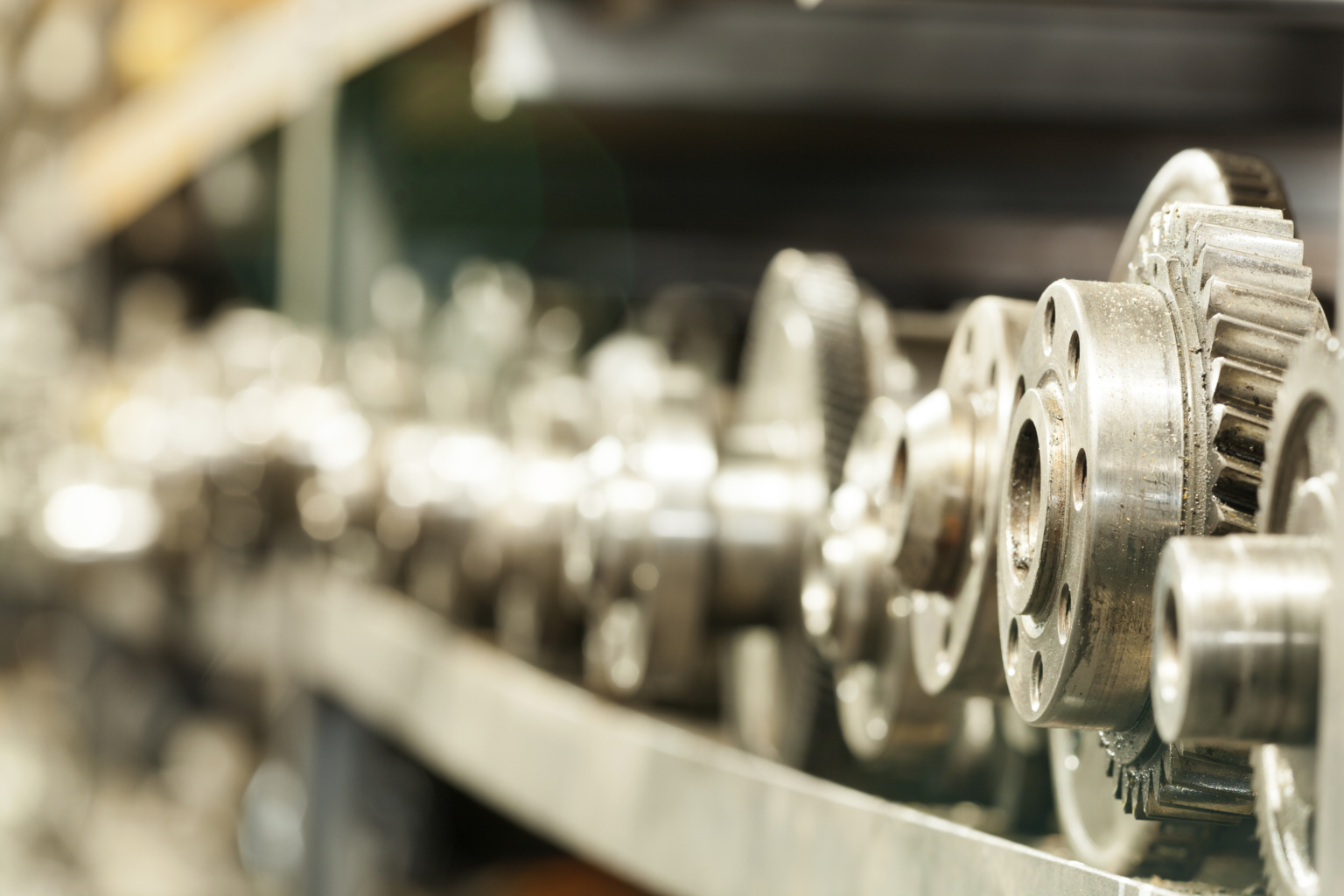

Durable cladding for Mining & Dredging Applications

Tardisphere is widely used in industries where equipment must endure the harshest conditions, including mining, dredging, and demolition. Whether it’s for dredging cylinder rods, pump and valve shafts, or mining tools, Tardisphere provides excellent protection against abrasive materials, external impacts, and corrosive environments. Its wear and corrosion resistance ensure that equipment remains operational longer, reducing downtime and maintenance costs in productivity-critical industries.

And, if damage does occur, repairs can easily be carried out in the field at low cost, without the need to dismantle the equipment.

Bearing surfaces and bushes

Tardisphere is ideal for bearing surfaces, particularly in water-lubricated environments where bronze bearings wear quickly. With its superior wear and corrosion resistance, Tardisphere extends component lifespan, even in highly corrosive conditions.

Topclad’s expertise also extends to bearing bushes coated with Tardisphere, which can be fitted directly on-site to propeller shafts. This approach saves time and minimizes downtime, ensuring fast, high-quality repairs. Whether for new or existing shafts, Tardisphere-coated bushes offer maximum durability without the need to transport equipment.

Tardisphere vs Standard tungsten carbide coatings

Tardisphere offers significant advantages over traditional tungsten carbide coatings, particularly in terms of corrosion resistance and impact toughness. While standard coatings are prone to cracking and delamination under heavy stress, Tardisphere’s metallurgical bond ensures a dense, pore-free structure that resists both corrosion and mechanical damage.

The result is a much more durable protective layer that extends the service life of critical components. Tardisphere also provides superior wear resistance, making it an ideal alternative to standard coatings in applications requiring both high impact resistance and extended durability.

Examples of markets and applications

Tardisphere is perfect for these markets and applications

We are Topclad

Topclad is Europe’s leading manufacturer of innovative laser clad layers, based in Lelystad, the Netherlands. We specialize in developing and applying laser clad layers for the most demanding industries, including oil & gas, offshore, dredging, mining, bridges & water locks, steel manufacturing, and food processing.

Our mission is to provide components with superior protection against wear, corrosion, and impact, resulting in significantly improved reliability and uptime of capital-intensive equipment. With over 14 years of experience and a steadfast commitment to quality, we deliver solutions that enhance the performance and longevity of your critical machinery.

Why Topclad?

- Over 16 years laser cladding experience with over 15.000 cladded components

- More than 10 in-house developed laser clad layers

- Commitment to quality

- Expertise in comprehensive repairs

- 24.000 mm clad length capacity and 2.200 clad diameter capacity

- Chromium-6-free solutions

Ready to talk

with us?

Topclad Laser Cladding is the leading manufacturer of innovative laser clad layers in Europe. Based in Lelystad, the Netherlands, Topclad Laser Cladding develops and applies laser clad layers for the most demanding industries including oil, gas, sustainable energy, offshore, dredging, mining, bridges and water locks, steel manufacturing and food processing.

"*" geeft vereiste velden aan