Introduction to Hard chrome plating

Hard chrome plating is an industrial electroplating technique used to enhance metal surfaces by applying a chromium layer. Known also as hard chromium or industrial chrome plating, this process is widely used in sectors like offshore, mining, and heavy equipment manufacturing. It improves wear resistance, corrosion protection, and reduces friction on critical components, making it a traditional go-to solution for engineers seeking enhanced surface performance.

Benefits of hard chrome plating for industrial applications

Hard chrome plating is a metal finishing process in which a layer of chromium is electrochemically deposited onto metal components. This layer provides:

- Increased wear resistance

- Improved corrosion protection

- Greater surface hardness

Due to these properties, hard chrome plating has long been valued for extending the lifespan of industrial equipment.

Key characteristics of Hard Chrome Plating

Hard chrome coatings are chosen for their distinct technical properties:

- Hardness: Reaching up to 65–69 HRC, ideal for high-durability applications.

- Wear and abrasion resistance: The hardness reduces wear, extending operational life.

- Corrosion resistance: Offers moderate protection in humid or corrosive environments.

- Low friction coefficient: Helps reduce energy loss and material degradation in moving parts.

- Material compatibility: Suitable for steel, stainless steel, cast iron, aluminum, and copper alloys.

The Hard Chrome Plating process

The hard chrome plating process typically involves three main steps:

- Surface preparation: The component is thoroughly cleaned to remove oils, dirt, and oxides. Proper surface preparation is crucial for adhesion and coating performance.

- Electrolytic deposition: The part is submerged in a chromic acid bath (~50–60°C). An electric current is applied, causing chromium ions to deposit onto the surface and form a chrome layer.

- Post-treatment: The part may undergo polishing, grinding, or finishing to achieve the desired smoothness and dimensional tolerances.

Typical hard chrome plating thickness ranges from 20 to 50 µm, depending on application needs.

Common applications in various industries

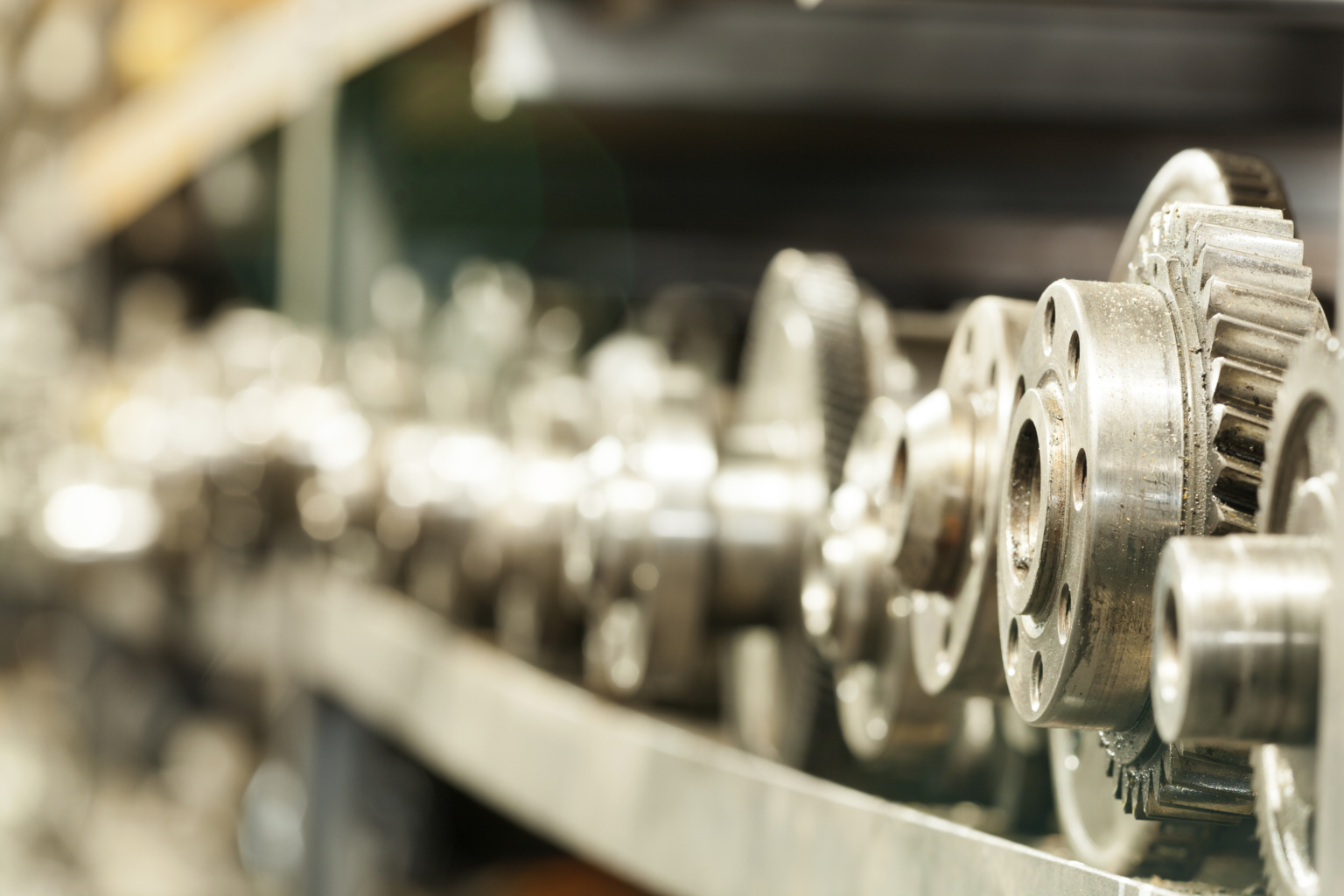

Hard chrome plating is used across a broad range of industrial components, including:

- Offshore & maritime: Pump shafts, drilling rods, components exposed to saltwater.

- Mining & heavy machinery: Hydraulic cylinders, piston rods, and excavator pins.

- Steel production: Rolling components and mechanical tools requiring high precision and durability.

These examples highlight the versatility of chrome coatings in wear-critical environments.

The limitations of Hard Chrome Plating

While hard chrome plating has been a standard solution in industrial surface treatment for decades, it comes with significant drawbacks, particularly under modern performance and sustainability demands. These drawbacks affect both operational reliability and long-term cost-efficiency.

Hazardous substances and regulatory pressure

The hard chrome plating process relies on hexavalent chromium (Cr VI), a highly toxic and carcinogenic substance. It is strictly regulated under REACH and similar frameworks worldwide. Compliance requires expensive safety systems, air filtration, waste treatment, and exposure controls. This not only increases operational complexity and cost, but also exposes businesses to legal and reputational risks. Laser cladding eliminates this problem entirely by using solid, safe feedstock materials and avoiding chemical baths altogether.

Micro-cracks reduce long-term durability

A major weakness of industrial hard chrome plating lies in its tendency to develop microscopic surface cracks during deposition and over time in service. These cracks, often invisible to the eye, create pathways for moisture, chemicals, and salt to penetrate beneath the chromium layer. This can lead to hidden corrosion, pitting, and eventual substrate failure — particularly in aggressive environments like offshore drilling, mining, or chemical processing. In contrast, newer technologies like laser cladding produce crack-free, dense surfaces, offering greater protection under real-world conditions.

Limited coating thickness and poor scalability

Typical chrome plating thickness ranges from 20 to 100 µm. In heavy-duty applications involving high wear, impact, or erosion, these thin layers can quickly degrade. Attempts to apply thicker coatings often result in poor adhesion, peeling, or internal stress fractures. This makes chrome unsuitable for parts that need both dimension rebuilding and enhanced surface durability. Laser cladding easily produces thicker, application-specific coatings. Even up to several millimeters, without sacrificing adhesion or structural integrity.

Weak mechanical bonding and delamination risk

The chromium layer is held to the base material by mechanical interlocking rather than chemical fusion. Under high vibration, fluctuating temperatures, or dynamic mechanical loads, this weak bond can fail, causing delamination, flaking, or catastrophic wear. By contrast, laser cladding creates a true metallurgical bond between coating and substrate, fusing the materials at the molecular level and virtually eliminating the risk of separation under extreme conditions.

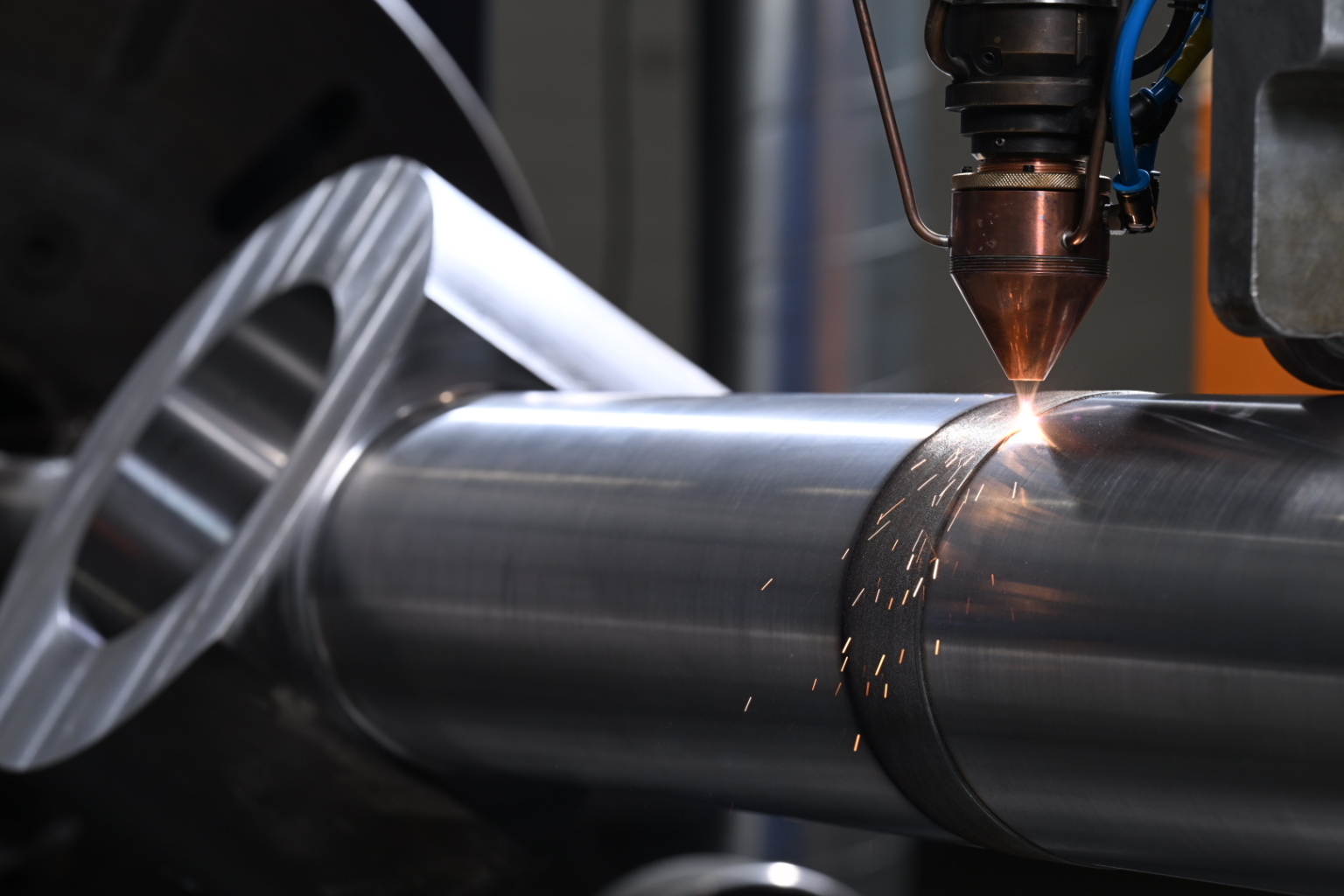

Alternative for Hard Chrome Plating

For industries seeking a superior alternative to hard chrome plating, laser cladding offers unmatched performance, safety, and versatility — far exceeding both traditional chrome and HVOF coatings. Laser cladding is the next-generation solution that addresses all limitations of hard chrome and outperforms HVOF (High Velocity Oxy-Fuel) coatings. It offers:

- Extreme wear resistance: Coatings last significantly longer in abrasive and high-load conditions.

- High impact resistance: Withstands mechanical shocks and pressure without cracking or delaminating.

- Strong metallurgical bond: The coating fuses with the base material, eliminating the risk of peeling or flaking.

- Custom coating thickness: From ultra-thin to several millimetres thick, tailored to your application’s exact needs.

- Optimised material choice: Coatings are engineered for specific environments, from chemical resistance to thermal loads.

- No hazardous chemicals: Unlike chrome or HVOF, laser cladding involves no toxic substances or waste streams.

- Minimal distortion: Localised heat input preserves the base material’s structure and geometry.

Laser cladding is not just an alternative, it is a future-proof solution for industries requiring durability, precision, and compliance.

Comparison: HCP vs. HVOF vs. Laser Cladding

| Feature | Hard Chrome Plating | HVOF Coating | Laser Cladding |

| Wear resistance | Moderate | Moderate | High |

| Corrosion protection | Limited | Limited | Excellent |

| Impact resistance | Low | Medium | High |

| Bonding strength | Weak (mechanical) | Medium (mechanical) | Strong (metallurgical) |

| Environmental impact | High (toxic waste) | High | Low (eco-friendly) |

| Application flexibility | Limited | Medium | High (tailored) |

| Thickness capability | ~50–100 µm | ~300 µm | Custom: from thin layers to >1 mm |

Industries benefiting from laser cladding

Topclad’s laser cladding technology is trusted in demanding industrial sectors:

- Offshore & maritime: Enhanced protection against seawater corrosion

- Mining & heavy equipment: Extended lifespan of wear-intensive components and even rebuild worn parts

- Steel industry: Clad coatings for rollers, press tools, and guides

- Bridges & water locks: increased durability for critical infrastructure.

- Food processing: Hygienic, corrosion-resistant coatings without contamination risk

Learn more about our industry-specific applications.

Laser clad layers

Learn more about the markets we serve

We are Topclad

Topclad is Europe’s leading manufacturer of innovative laser clad layers, based in Lelystad, the Netherlands. We specialize in developing and applying laser clad layers for the most demanding industries, including oil & gas, offshore, dredging, mining, bridges & water locks, steel manufacturing, and food processing.

Our mission is to provide components with superior protection against wear, corrosion, and impact, resulting in significantly improved reliability and uptime of capital-intensive equipment. With over 16 years of experience, a steadfast commitment to quality, and a proven track record of over 15,000 laser cladded components, we deliver solutions that enhance the performance and longevity of your critical machinery.

Why Topclad?

- Over 16 years laser cladding experience with over 15.000 cladded components

- More than 10 in-house developed laser clad layers

- Commitment to quality

- Expertise in comprehensive repairs

- 24.000 mm clad length capacity and 2.200 clad diameter capacity

- Chromium-6-free solutions