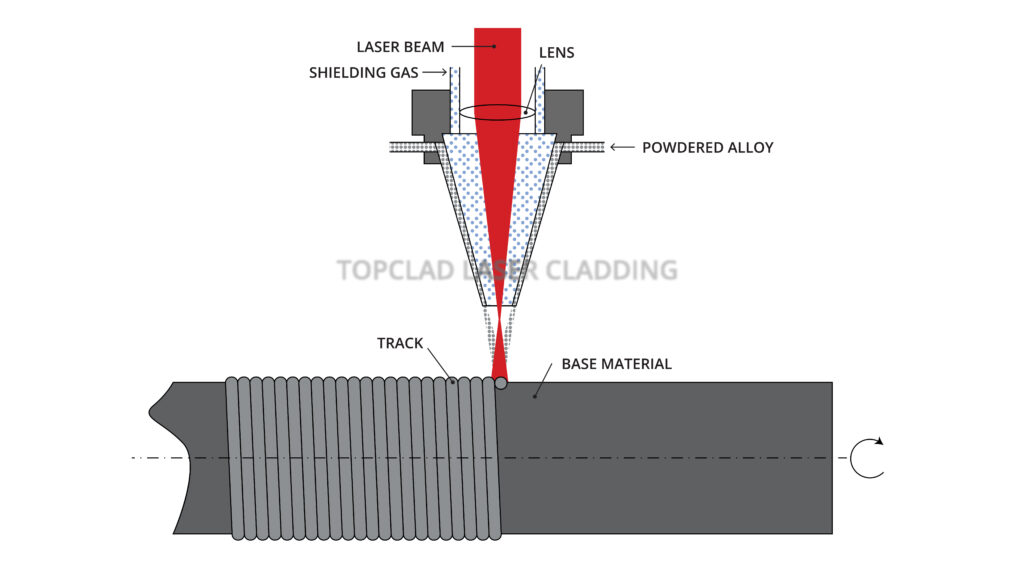

Precisely controlled laser beam

The process of laser cladding begins with a precisely controlled laser beam directed onto the substrate’s surface. This focused laser beam generates a localized, high-energy density heat source that melts the powdered alloy material. The alloy material is carefully selected based on the application requirements, ensuring optimal properties such as corrosion resistance, wear resistance, and thermal stability.

Minimized heat transfer

One of the key advantages of laser cladding lies in its ability to minimize heat transfer to the substrate. By focusing the laser energy, only a small area undergoes thermal exposure, preventing substantial changes in the substrate’s physical properties. This precision ensures that the original shape and dimensions of the substrate are preserved, crucial for maintaining component integrity and functionality.

Instant metallurgical bonding

Metallurgical bonding between the melted alloy and substrate occurs instantly as the molten material solidifies. This bond is characterized by its pore-free and crack-free nature, which significantly enhances the coating’s reliability and durability. The resultant surface exhibits superior properties compared to traditional coatings like nickel-chrome plating (NiCr) and high-velocity oxygen fuel (HVOF) spraying, making laser cladding an indispensable choice for critical applications.

Technical, economic and environmental benefits

Laser cladding provides significant technical, economic, and environmental benefits for industrial applications. For a deeper understanding of the advantages and disadvantages of laser cladding, visit our dedicated page Advantages and Disadvantages of Laser Cladding.

Precision tailored for critical applications

Our specialized equipment adeptly handles components of various sizes and complexities. From small, delicate parts to large components with diameters up to 2200 mm and lengths up to 24000 mm, our capability ensures precision and efficiency for every project. This is particularly crucial for applications where extreme accuracy is demanded under challenging conditions.

Technological leadership in surface treatment

We have developed proprietary laser clad layers, such as those superior to widely used materials like Inconel 625, distinguishing our offerings with enhanced corrosion resistance, ductility, and wear resistance. With over 14 years of experience, our technological expertise not only extends equipment lifespan and boosts performance but also significantly reduces operational costs for our clients.

Custom solutions for complex needs

Recognizing the uniqueness of each project, Topclad provides custom solutions specifically designed to improve wear resistance, corrosion resistance, and thermal stability. Our laser cladding technology consistently delivers superior results compared to traditional methods like nickel-chrome plating (NiCr) and HVOF spraying. We also excel in applying both thick and exceptionally thin layers, adept at both new component treatment and repair/restoration work, ensuring that even the most critical applications receive the most effective surface treatment available.