Quarite serie

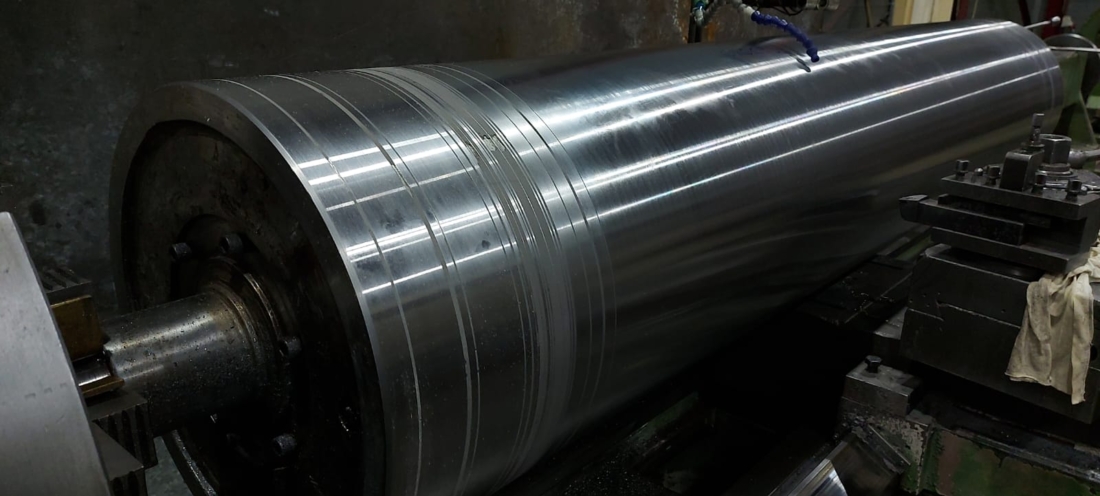

Developed with precision, Quarite layers bring together superior wear resistance and outstanding corrosion protection, making them an essential choice for demanding industrial applications. Engineered for both new components and repair projects, these layers are tailored to enhance performance and longevity in challenging environments. Whether for heavy-duty machinery, rotating shafts, or other critical equipment, Quarite layers offer unparalleled durability without compromising efficiency. Explore our range to discover how these innovative coatings can optimize your operations.

Optimized for many applications, Quarite N offers excellent corrosion resistance and strong chemical & thermal propertie

Quarite NR provides the highest corrosion resistance in the Topclad portfolio, ideal for environments with extreme corrosion and moderate wear demands.

Quarite NR+ combines exceptional corrosion resistance (equal to NR) with enhanced wear resistance, making it perfect for harsh, most challenging environments.

Specially developed to combine the best of both worlds—excellent corrosion resistance and high wear resistance—without using carbides.

Quarite’s key applications

Quarite layers are specifically designed for applications requiring a balance of high wear resistance and excellent corrosion protection. They are versatile, suitable for both new components and repairs. Key applications include:

- Heavy-duty cylinder rods – Ideal for equipment exposed to frequent motion and wear.

- Rotating shaft ends – Ensures durability in components subject to both wear and corrosive environments.

- Bearing liners – Provides wear resistance and enhances lifespan in demanding conditions.

- Mandrels – Protects against wear and corrosion in high-stress environments.

- Counterparts of seals in corrosive environments – Offers reliable protection against corrosion and wear where sealing mechanisms are critical.

These applications highlight Quarite’s adaptability in industries such as heavy machinery, manufacturing, and other environments with combined wear and corrosion challenges.

Examples of key markets

Quarite layers are suitable for a wide range of markets where durability, corrosion resistance, and wear protection are crucial. Key markets include:

Ready to talk

with us?

Topclad Laser Cladding is the leading manufacturer of innovative laser clad layers in Europe. Based in Lelystad, the Netherlands, Topclad Laser Cladding develops and applies laser clad layers for the most demanding industries including oil, gas, sustainable energy, offshore, dredging, mining, bridges and water locks, steel manufacturing and food processing.

"*" geeft vereiste velden aan