Topclad laser clad layers vs. traditional coatings

By choosing Topclad’s laser cladding solutions, industries can achieve better long-term protection and performance, ensuring higher uptime and reduced operational costs. These advantages clearly distinguish Topclad’s laser clad layers from traditional coatings, making them the preferred choice for industries seeking reliable, durable, and efficient protective solutions.

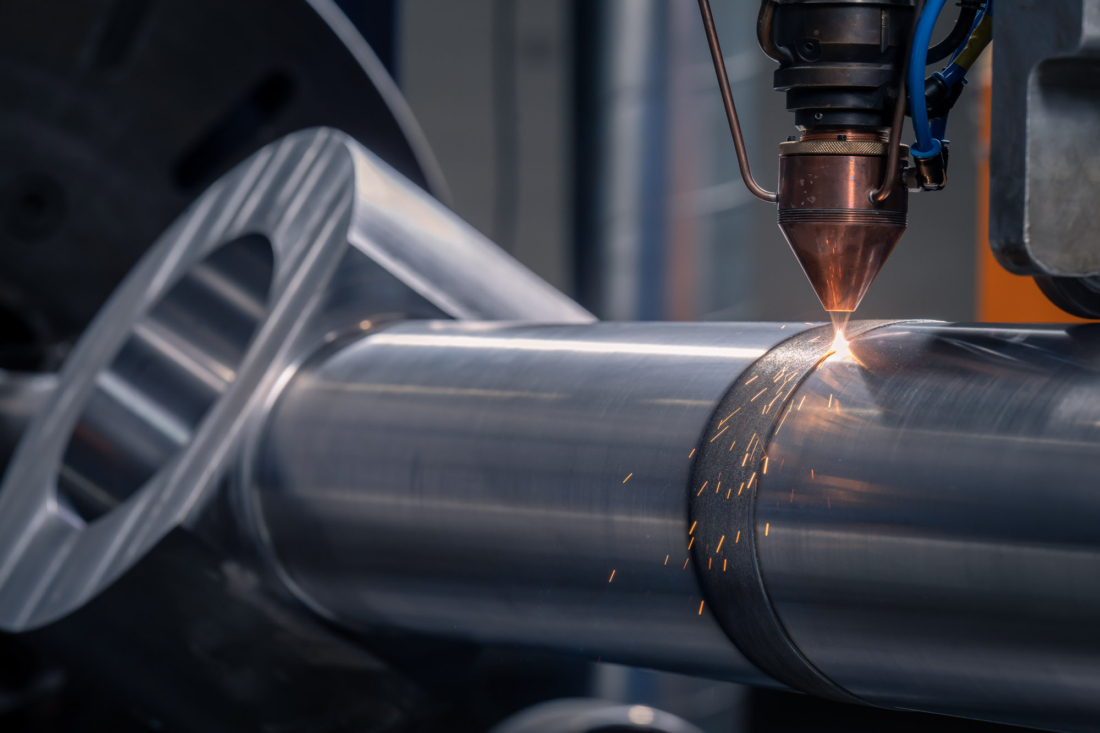

Over the years, Topclad has developed an extensive range of laser clad layers, engineered to meet the varied needs of our customers across multiple industries. Our laser cladding layers have been rigorously tested in collaboration with our customers, suppliers, and notified bodies to ensure they meet and exceed industry standards.

Nickel-Chrome Plating

Nickel-chrome (NiCr) plating has long been used for corrosion protection on hydraulic rods, valves, and other components in industries like oil & gas and marine. However, in harsh environments, NiCr often struggles with wear, corrosion, and vulnerability to impact and thermal shocks. Many customers are now choosing laser cladding for its fully sealed, non-porous layer, which provides superior durability without harmful hexavalent chromium (Cr6).

With NiCr as a common traditional method, it serves as a reference point in comparing the long-term performance and environmental benefits of laser cladding.

Differences explained

The key differences between traditional coatings and Topclad’s laser clad layers are:

- Intermetallic bonding: Laser cladding forms an intermetallic bond by melting the alloy with the base material, unlike HVOF and NiCr coatings, which use mechanical bonding. This prevents sub corrosion and cracking, ensuring better protection against environmental elements like saltwater and thermal shocks.

- High ductility: Topclad’s laser clad layers absorb stress from impacts, bending, and temperature changes without cracking. This makes them far more durable in harsh operational environments than HVOF and NiCr coatings, which are more brittle and prone to cracking.

- Zero porosity: Laser cladding creates an impermeable barrier, completely preventing corrosive elements from penetrating the material, offering better corrosion resistance compared to traditional coatings, which can contain pores that allow water ingress.

- Repair and overhaul capabilities: Laser cladding allows efficient repairs by applying layers varying from 200 microns to several millimetres of clad material to damaged areas, restoring parts to their original condition without the need for full replacements—an option unavailable in HVOF and NiCr processes.

- Versatility in material use: Laser cladding can be applied to a wide range of materials, including carbon steels, stainless steels, duplex steel, nickel-based alloys, and more. This versatility allows for customized solutions tailored to specific industrial requirements.