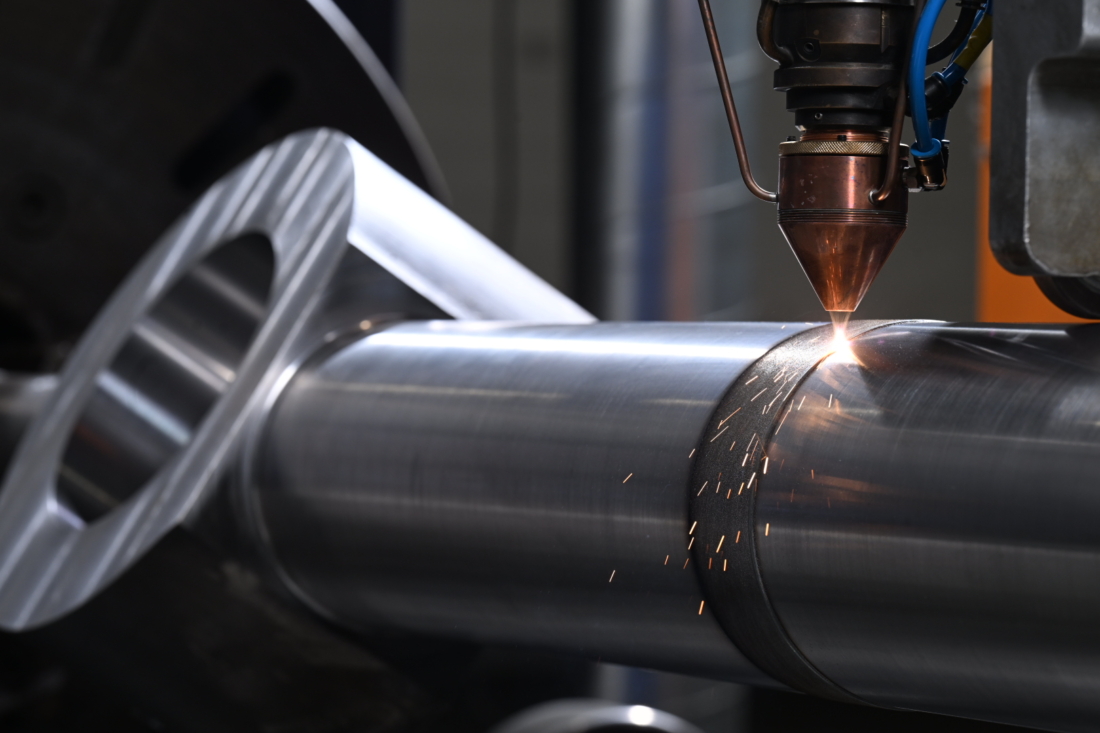

Laser clad layer Ultimet

Topclad’s Ultimet layer is a cobalt-based alloy applied through precision laser cladding. This metallurgically bonded coating offers a balance of toughness, wear resistance, and corrosion protection—ideal for components operating under severe mechanical and chemical exposure.

Ultimet – cobalt-based laser clad layer for extreme wear and corrosion

Ultimet is a cobalt-chromium-molybdenum-nickel alloy designed for use in harsh environments where conventional coatings fall short. Ultimet resists wear, impact and chemical attack, making it highly suitable for dynamic, high-load or corrosive conditions. The layer is provided with a laser clad layer, enabling exact thickness control and metallurgical bond with the base material.

Benefits of Ultimet

- No delamination

The metallurgical bond ensures the layer won’t chip or flake off. - Built for the demanding conditions

Ultimet performs reliably in corrosive and high-impact environments, making it ideal for components exposed to aggressive media and mechanical shock. - High ductility

Absorbs dynamic loads and prevents cracking under stress. - Thermal shock resistant

Maintains integrity under rapid temperature changes. - High temperature operation

Suitable for applications up to 900°C.

Advantages over traditional coatings

- Tough and impact-resistant – Unlike brittle coatings such as HVOF or ceramics, this layer can absorb shocks and localized stress.

- High corrosion resistance – Particularly effective in chloride-rich and acidic environments.

- Recladding possible – The layer can be restored multiple times without replacing the base material.

- No delamination – The metallurgical bond ensures the layer won’t chip or flake off.

- Precision repairs – Laser cladding allows highly targeted repairs and fine control over layer thickness.

Applications

Ultimet is typically used in shafts, hydraulic cylinders, rollers and high value machine components that face above average mechanical wear or chemical exposure. It is ideal for both original equipment and repair of high-value parts that must maintain integrity under stress.

Need help?

Price information

Why cobalt-based layers make the difference

Compared to traditional coatings like hard chrome, HVOF or nickel-based alloys, cobalt-based layers provide superior toughness and impact resistance. They maintain their protective properties even when subjected to high point loads or cyclic stresses, and resist cracking, chipping, or corrosion in conditions that degrade most alternatives.

Other products in this serie

Aluminium bronze is a highly durable alloy, known for its excellent corrosion resistance and outstanding sliding properties

A high-performance nickel-chromium-based alloy known for its high strength properties and resistance to corrosion, oxidation, and high temperatures.

Stainless Steel 316 is a versatile and durable alloy known for its corrosion resistance, particularly in harsh environments

This cobalt-chromium alloy is known for its hardness, corrosion resistance, and performance in challenging environments.

Known for corrosion resistance, chemical and thermal shock resilience. Ideal for new components and repairs.

We are Topclad

Topclad is Europe’s leading manufacturer of innovative laser clad layers, based in Lelystad, the Netherlands. We specialize in developing and applying laser clad layers for the most demanding industries, including oil & gas, offshore, dredging, mining, bridges & water locks, steel manufacturing, and food processing.

Our mission is to provide components with superior protection against wear, corrosion, and impact, resulting in significantly improved reliability and uptime of capital-intensive equipment. With over 16 years of experience, a steadfast commitment to quality, and a proven track record of over 15,000 laser cladded components, we deliver solutions that enhance the performance and longevity of your critical machinery.

Why Topclad?

- Over 16 years laser cladding experience with over 15.000 cladded components

- More than 10 in-house developed laser clad layers

- Commitment to quality

- Expertise in comprehensive repairs

- 24.000 mm clad length capacity and 2.200 clad diameter capacity

- Chromium-6-free solutions