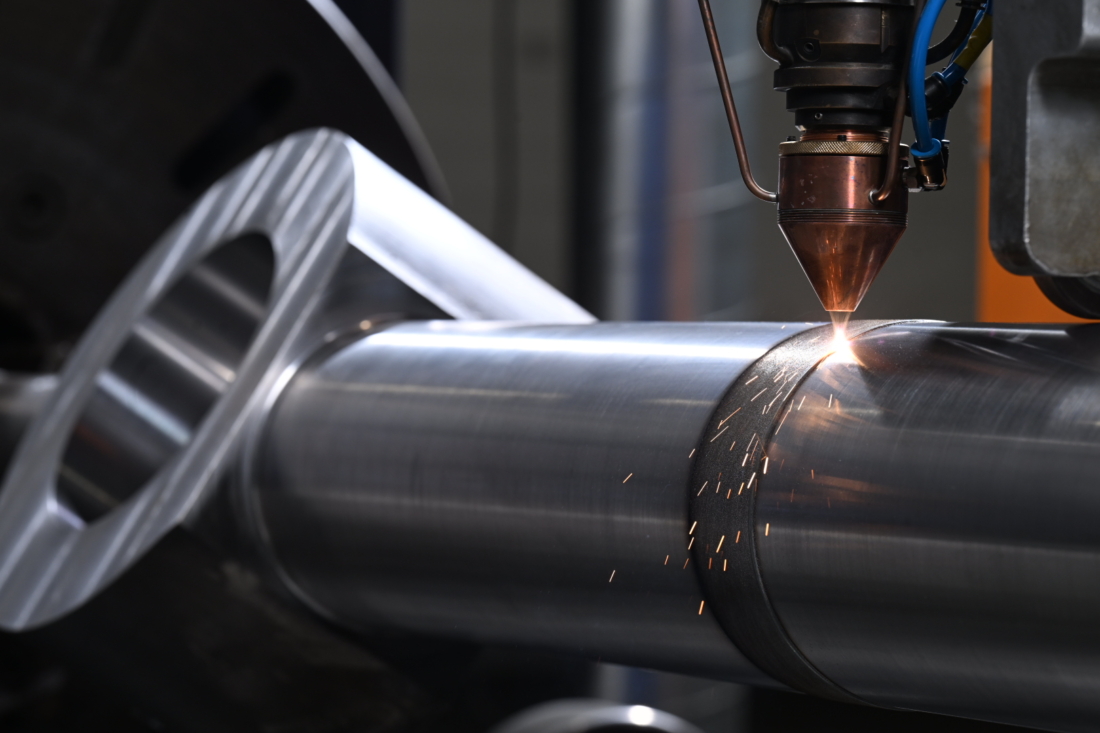

Laser clad layer Quarite N

Quarite N is a versatile and robust laser clad layer renowned for its superior corrosion and thermal resistance. It is designed for a broad range of applications where reliability and lifespan are critical, preventing issues like peeling or cracking. This ensures no loose particles can disrupt your machinery, thereby preventing equipment failures and costly downtimes.

Long-term protection with low TCO

Quarite N offers a cost-effective solution. Offering over four times the corrosion resistance of traditional coatings as well as by being competitively priced against traditional nickel-chrome coatings, Quarite N provides long-term protection at competitive initial costs, with an overall lower cost of ownership. This makes Quarite N an ideal choice for industries focused on both performance and cost-efficiency, particularly in environments demanding high resistance to corrosion and chemical exposure.

Benefits of Quarite N

Quarite N is a cost-effective solution that combines high-performance corrosion resistance with advanced chemical resistance. Its key features include:

- Corrosion resistance

Quarite N offers excellent protection, making it ideal for use in environments where corrosion is a significant issue. - Chemical resistance

With its robust structure, Quarite N provides strong resistance against chemicals, ensuring longer operational life for machinery, especially in the food, chemical, and recycling industries. Quarite N resists a large number of acids and lye, which are commonly used in the food industry, making it highly suitable for such environments. - Thermal shock resilience

It can endure fluctuating temperatures, maintaining its integrity under high thermal stress. The secret behind this is the high ductility of this Topclad coating. - Impact resistance and easy repair

In the case of external impacts, Quarite N demonstrates its ductile capabilities, preventing cracks or blisters and hence no corrosion. If repair is needed, it can be done easily on-site without dismantling the equipment. - Cost-effectiveness

Compared to traditional coatings, Quarite N provides better protection while remaining cost-competitive, especially when compared to nickel-chrome platings.

Quarite N vs Traditional Coatings

Quarite N offers at least four times the corrosion resistance of traditional nickel-chrome (NiCr) coatings, significantly improving equipment durability and reducing maintenance costs. This laser clad layer is not only technically superior but also economically competitive, providing strong protection at a competitive price. While NiCr is prone to porosity, sub-corrosion, and peeling, Quarite N’s dense, pore-free structure delivers robust defense in the harshest environments.

Additionally, traditional coatings can lead to oil leaks in hydraulic systems, causing environmental damage, particularly in surface waters, and system malfunctions due to chrome blisters clogging hydraulic valves and filters. Quarite N mitigates these risks, offering long-term protection, making it the optimal choice for industries looking to minimize downtime and achieve a lower total cost of ownership.

Reliable machine parts with Quarite N

Contact us today to discuss how Quarite N can protect your equipment in even the harshest environments. With proven resistance to chemicals, corrosion, and thermal stress, Quarite N ensures your machinery operates at optimal efficiency for extended periods. Request a quote today and discover how Quarite N can enhance the lifespan of your critical components and reduce overall maintenance costs.

Need help?

Price information

Other products in this serie

Optimized for many applications, Quarite N offers excellent corrosion resistance and strong chemical & thermal propertie

Quarite NR provides the highest corrosion resistance in the Topclad portfolio, ideal for environments with extreme corrosion and moderate wear demands.

Quarite NR+ combines exceptional corrosion resistance (equal to NR) with enhanced wear resistance, making it perfect for harsh, most challenging environments.

Specially developed to combine the best of both worlds—excellent corrosion resistance and high wear resistance—without using carbides.

Examples of markets and applications

Quarite N is perfect for these markets and applications

We are Topclad

Topclad is Europe’s leading manufacturer of innovative laser clad layers, based in Lelystad, the Netherlands. We specialize in developing and applying laser clad layers for the most demanding industries, including oil & gas, offshore, dredging, mining, bridges & water locks, steel manufacturing, and food processing.

Our mission is to provide components with superior protection against wear, corrosion, and impact, resulting in significantly improved reliability and uptime of capital-intensive equipment. With over 16 years of experience, a steadfast commitment to quality, and a proven track record of over 15,000 laser cladded components, we deliver solutions that enhance the performance and longevity of your critical machinery.

Why Topclad?

- Over 16 years laser cladding experience with over 15.000 cladded components

- More than 10 in-house developed laser clad layers

- Commitment to quality

- Expertise in comprehensive repairs

- 24.000 mm clad length capacity and 2.200 clad diameter capacity

- Chromium-6-free solutions