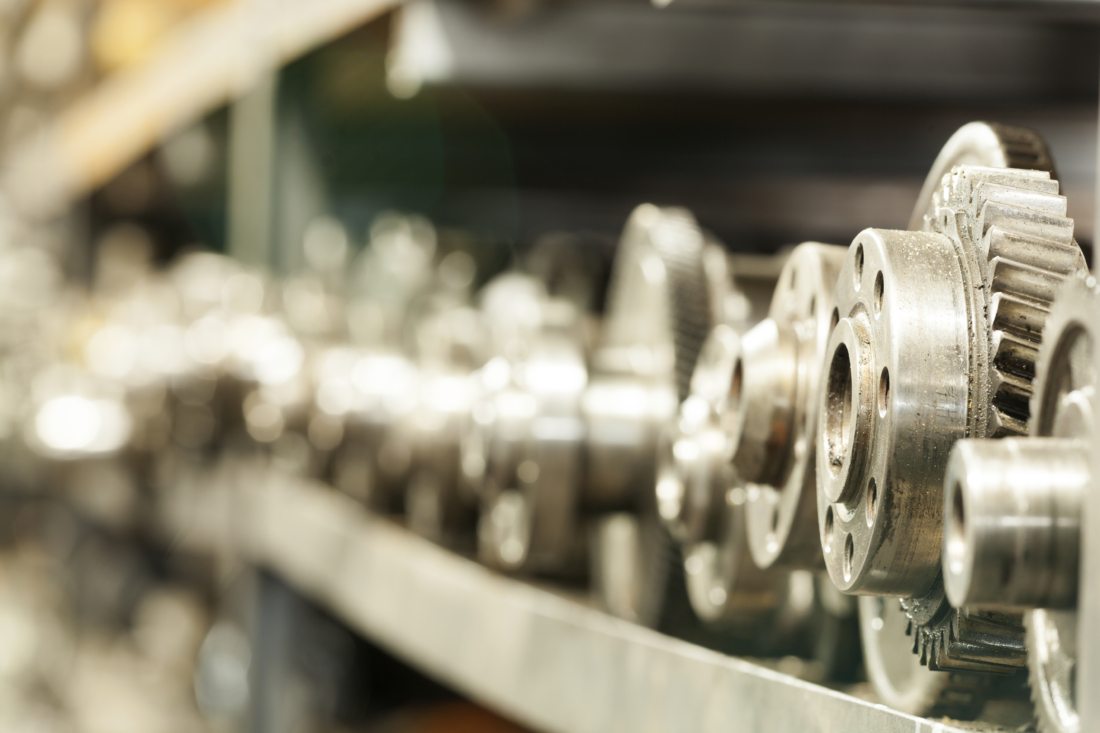

Repair machine parts

Machine parts are often subjected to extreme operational stress, wear, and tear, which can lead to deterioration over time. From shafts to rolls and drums, wear-out is inevitable in harsh environments or heavy-duty use. Laser cladding provides a reliable, efficient solution to restore worn-out machine parts, reducing the need for costly replacements and extending their service life.

By proactively cladding new machine parts, you can extend their lifespan and reduce the likelihood of breakdowns. With laser cladding, you not only restore the functionality of existing components but also safeguard your equipment for the future. Whether it’s about bringing a machine part back to its optimal state or adding a protective layer to prevent further damage, Topclad laser cladding is the go-to partner for achieving superior durability and performance. Discover more about our markets and learn how we restore machine parts to as-new conditions across industries like steel, mining, and food processing.

How to repair worn out machine parts

Worn-out machine parts can be effectively repaired through laser cladding. This advanced technique involves applying a precisely controlled layer of an in-house engineered alloy onto the surface of the part, which not only restores its original dimensions but also provides wear resistance, impact resistance, and protection against corrosion. By reinforcing the surface with laser cladding, you enhance the overall strength and durability of your components, reducing the risk of further wear or mechanical failure.

At Topclad, we specialize in restoring worn-out machine components by machining down damaged sections, removing existing layers, and applying fresh cladding to bring the parts back to their original specifications. We can add new material up to several millimeters thick, using various alloys depending on the specific needs of the part. Whether it’s worn-out surfaces that require a whole new protection layer or damaged threads requiring new, precision-machined threads to ensure a perfect fit, we can do it. Our expertise allows us to handle even the most demanding repairs, extending the life and reliability of your equipment.

Depending on the use of the machine parts, we apply different specialized layers, such as Quarite NR, which is highly recommended for its excellent corrosion protection and wear resistance in challenging environments. When radial wearing is common, our Thardisphere layer provides solid protection. Learn more about our solutions for industrial applications, and see how we provide industry-leading cladding services.

Repair worn out machine parts in Lelystad, the Netherlands

For reliable machine part repairs, Topclad is the trusted partner across industries. With over 16 years of experience and a proven track record spanning more than 15,000 laser cladded components, we are equipped to restore everything from standard-sized parts to oversized components. Our laser cladding technology ensures that even the most severely worn parts are rejuvenated with precision, bringing them back to optimal functionality.

At Topclad, we not only restore worn parts but also enhance them to perform better than before. Our expert team ensures that all repairs are completed with attention to detail, using advanced materials to withstand the harshest conditions. This enables businesses to reduce downtime, save on operational costs, and achieve greater equipment reliability.

Make your machines more reliable with laser cladding

Take the next step to ensure your machines run efficiently and reliably. Request a quote today and let Topclad provide you with a solution that maximizes the lifespan of your equipment and optimizes your operational efficiency. Contact us for expert advice and see how we can help extend the life of your machine parts.

Laser clad layers for machine parts

Excellent corrosion and wear resistance, ideal for dredging and mining, or as a bearing surface.

Sinex replaces full material stainless steel with a laser clad layer on carbon steel, matching 316L's properties.

Optimized for many applications, Quarite N offers excellent corrosion resistance and strong chemical & thermal propertie

Quarite NR provides the highest corrosion resistance in the Topclad portfolio, ideal for environments with extreme corrosion and moderate wear demands.

Quarite NR+ combines exceptional corrosion resistance (equal to NR) with enhanced wear resistance, making it perfect for harsh, most challenging environments.

Specially developed to combine the best of both worlds—excellent corrosion resistance and high wear resistance—without using carbides.

Markets

Laser cladding for machine parts repair is used in these industries:

Ready to talk

with us?

Topclad Laser Cladding is the leading manufacturer of innovative laser clad layers in Europe. Based in Lelystad, the Netherlands, Topclad Laser Cladding develops and applies laser clad layers for the most demanding industries including oil, gas, sustainable energy, offshore, dredging, mining, bridges and water locks, steel manufacturing and food processing.

"*" geeft vereiste velden aan

We are Topclad

Topclad is Europe’s leading manufacturer of innovative laser clad layers, based in Lelystad, the Netherlands. We specialize in developing and applying laser clad layers for the most demanding industries, including oil & gas, offshore, dredging, mining, bridges & water locks, steel manufacturing, and food processing.

Our mission is to provide components with superior protection against wear, corrosion, and impact, resulting in significantly improved reliability and uptime of capital-intensive equipment. With over 16 years of experience, a steadfast commitment to quality, and a proven track record of over 15,000 laser cladded components, we deliver solutions that enhance the performance and longevity of your critical machinery.

Why Topclad?

- Over 16 years laser cladding experience with over 15.000 cladded components

- More than 10 in-house developed laser clad layers

- Commitment to quality

- Expertise in comprehensive repairs

- 24.000 mm clad length capacity and 2.200 clad diameter capacity

- Chromium-6-free solutions