Nickel Chrome

Nickel chrome, also known as nickel chrome plating or nickel-chromium coating, is a widely used technique for protecting industrial components against wear and corrosion. The coating is praised for its bright finish and moderate durability. Typically, it’s applied as a thin galvanic layer. On this page, we explain what nickel chrome is, when it’s used, and why laser cladding has become the preferred alternative in many demanding applications.

What is Nickel Chrome?

Nickel chrome refers to both an alloy and a coating. The alloy consists mainly of nickel and chromium and is known for its heat and corrosion resistance. In coating applications, the process involves two galvanic layers: a base layer of nickel, followed by a chromium topcoat. This is often called duplex plating. The alloy’s chemical formula is NiCr and it’s commonly known as nichrome.

The plating offers a shiny finish and some level of corrosion resistance. However, because the bond to the base material is mechanical—not metallurgical—its long-term performance is limited, especially in harsh environments.

Nickel Chrome properties

Nickel chrome alloys and coatings offer several notable properties:

Heat resistance

- High melting point: approx. 1400–1600°C, depending on the specific alloy

- Excellent oxidation resistance at elevated temperatures

- Stable electrical resistance under heat. Useful in heating elements and resistors

Corrosion resistance

- Adequate resistance to rust and many corrosive environments

- Moderate protection in mildly aggressive chemical environments

- Improved performance when combined with nickel in a duplex layer

- Common in stainless steel production as a key alloying element

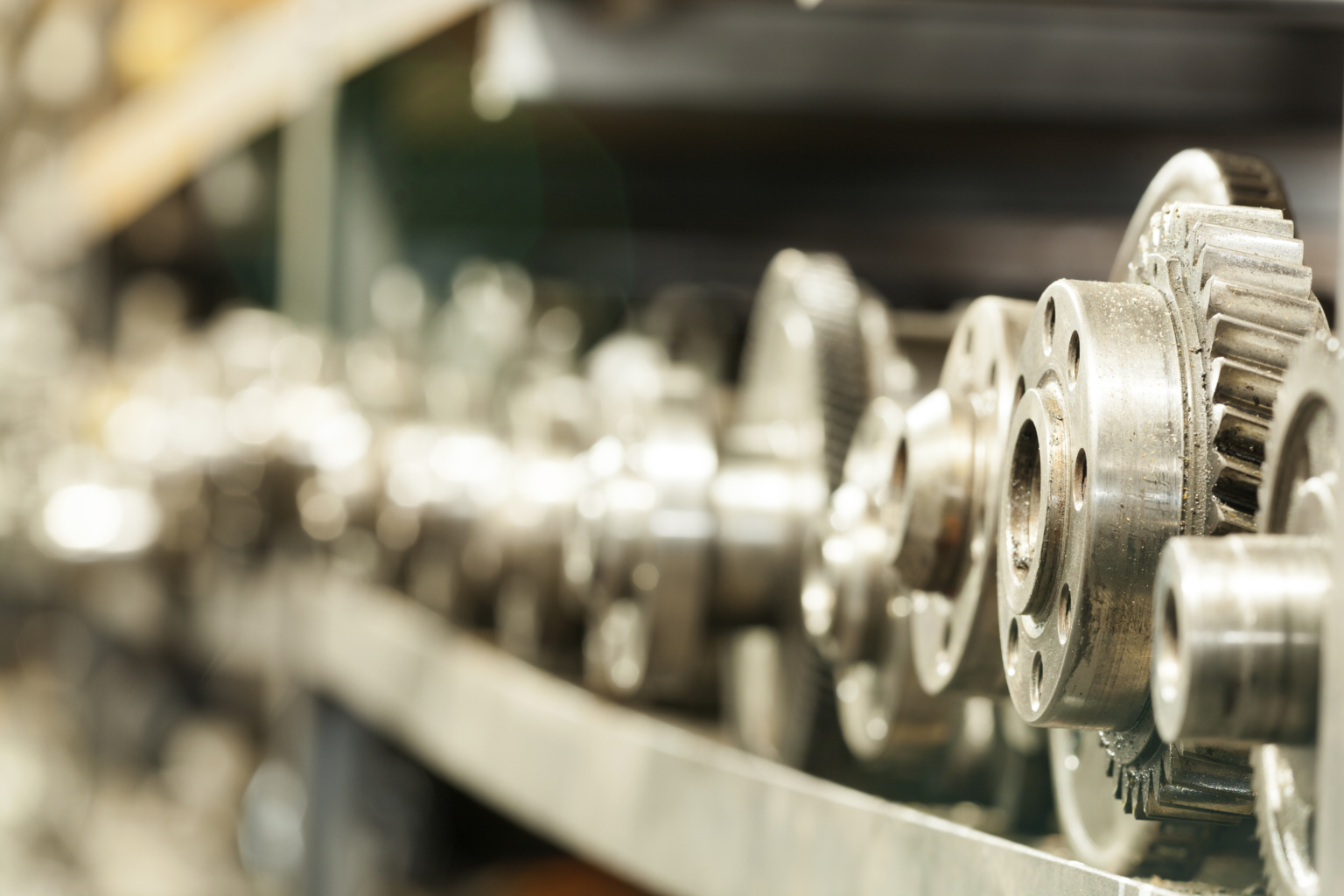

Nickel Chrome applications

Composition of Nickel Chrome

Industries using nickel chrome include:

- Oil & Gas: valves, connectors, and downhole tools

- Chemical processing: tanks, piping systems, and heat exchangers

- Maritime & Offshore: propeller shafts, exposed hardware, and protective coatings

- Heavy machinery: piston rods, hydraulic cylinders, rollers

- Heating technology: electrical heating elements and resistive wire components

Its strength lies in handling high temperatures and moderate corrosion. That makes it suitable for parts exposed to thermal loads and basic chemical exposure.

Most nickel chrome alloys contain 80% nickel and 20% chromium. Variants exist for different uses. Some include up to 5% iron for improved ductility while retaining corrosion resistance. Common compositions include:

- NiCr 80/20 (most used)

- NiCrFe 60/20/20 (with iron)

- NiCr 70/30 (more chromium for specific thermal applications)

Advantages of Nickel Chrome

Nickel chrome and nickel chrome plating offer several advantages:

- Corrosion and heat resistance Performs moderately well in harsh or hot environments

- Strong adhesion Bonds well when plating is carefully controlled

- Alternative to stainless steel: Useful when full stainless construction is too expensive

These qualities made it a popular choice in industrial and consumer products for decades.

Disadvantages of Nickel Chrome

Despite its advantages, nickel chrome plating has several drawbacks:

Poor sealing and corrosion performance

Nickel chrome layers are inherently porous. In aggressive environments, such as marine or offshore industry, fluids like seawater can penetrate through the coating. Once underneath, corrosion begins on the steel surface and pushes the chrome outward, often causing blistering and delamination from within.

Limited bonding strength

Unlike laser cladding, which creates a metallurgical bond with the substrate, nickel chrome forms only a mechanical bond. This makes it more prone to delamination and chipping under stress, vibration, or impact.

Microcracks under stress

The chromium layer develops microcracks in corrosive or high-pressure settings. These cracks reduce surface integrity and accelerate wear.

Difficult to repair

Once damaged, nickel chrome is hard to fix. Repairs require full stripping and replating, which adds downtime and cost. The process also limits layer thickness to 1–2 passes. Thicker layers increase the risk of cracking.

Not food-grade safe in all cases

Cracks or flaking may lead to contamination—unacceptable in hygienic industries like food processing.

Non-uniform coating

Electroplating has low cathode efficiency. Coatings are thicker at edges, thinner in corners. This causes uneven protection.

Material waste and high costs

Full surface plating uses more nickel and chromium than necessary, raising costs without added performance.

These disadvantages make nickel chrome less suited to modern industry, where durability, reparability, and precision matter most.

Alternative for Nickel Chrome

While nickel chrome was long considered the standard, it’s now often replaced by laser cladding. This is a more durable, efficient, and sustainable process. Laser cladding offers better protection, longer life, and lower total cost.

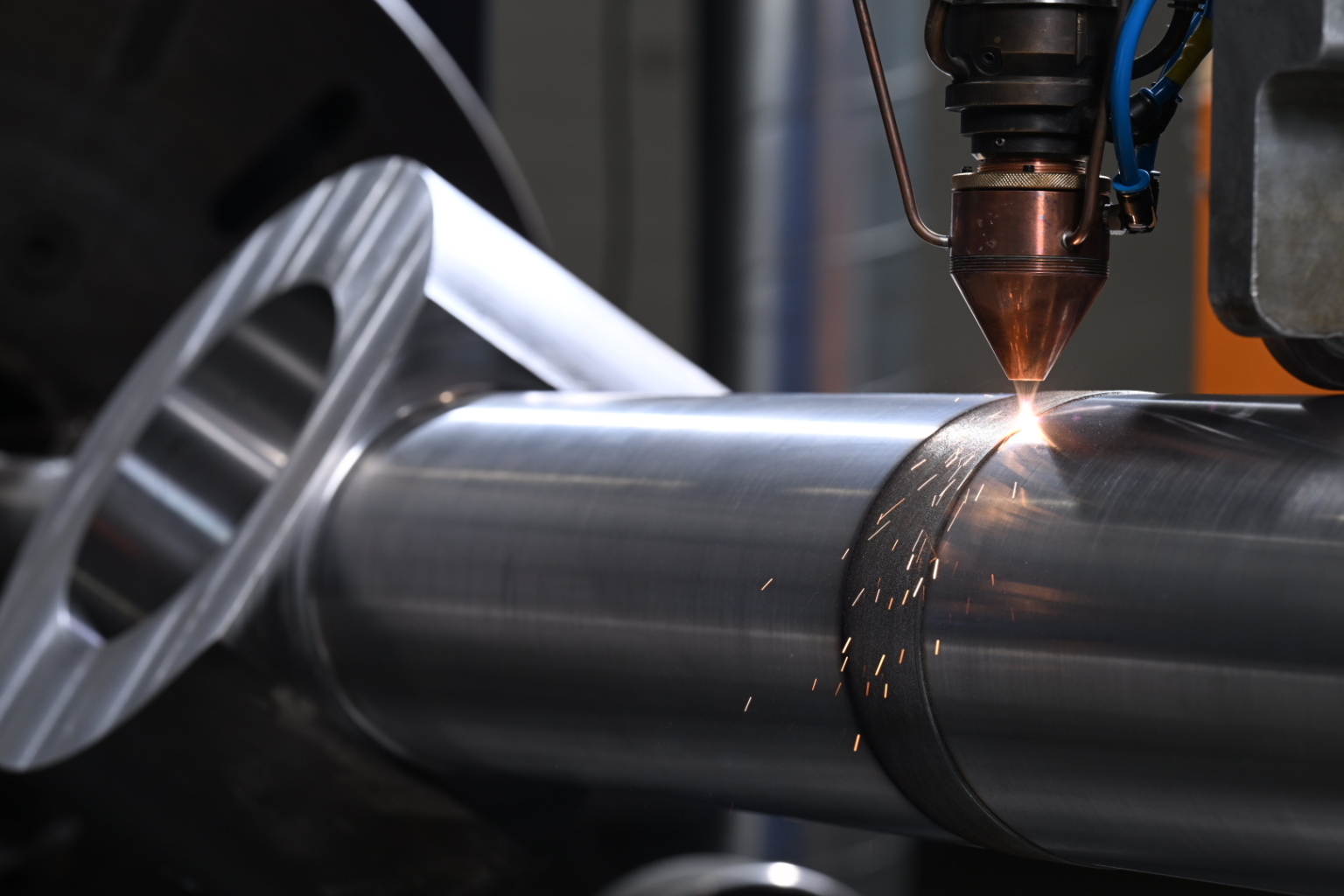

What is laser cladding?

Laser cladding uses a high-energy laser to apply a wear-resistant alloy to a metal surface. The process creates a thin layer with a metallurgical bond, not a mechanical one. This layer is fused directly to the base material. This bond ensures superior performance under mechanical or thermal stress.

Only wear zones are clad. The rest of the part stays uncoated, saving on expensive materials. Common base materials include carbon steel. Typical layer thickness ranges from 0.225 mm to several millimeters.

Laser cladding offers several advantages over conventional coating techniques like HVOF (High Velocity Oxygen Fuel spraying) or Nickel Chrome coating:

- High Performance: Laser-clad layers provide superior performance to wear, impact and corrosion resistance to solid nickel chrome.

- Superior bonding: Laser cladding achieves a metallurgical bond with the substrate—far stronger than mechanical or sprayed layers.

- Cost savings: Only the wear zones are clad—no need to use expensive alloy for the entire component.

- Material efficiency: The laser clad layer is applied precisely where needed, eliminating over-engineering.

- Custom layer thickness: Cladding thickness can be tailored to match wear needs, from 0.225 to several millimeters.

- Longer lifespan: Clad surfaces can be machined off and re-clad after wear repeatedly, extending component life significantly.

- Easy local repair: Minor damages can be repaired using standard TIG welding equipment. Hence, no need to dismantle, replace or fully reprocess the part.

Why laser cladding is superior

Laser cladding outperforms nickel chrome in almost every area:

Superior bonding

Laser cladding fuses the protective layer into the base material. This prevents delamination, even in parts subject to shock, vibration, or bending. Nickel chrome, which relies on mechanical adhesion, fails under such stress.

Thicker and stronger layers

Nickel chrome can’t handle thick layers. Beyond a certain point, cracks form. Laser cladding applies thick coatings without loss of adhesion. That makes it ideal for restoring worn parts to original specs.

Outstanding wear and corrosion resistance

Laser cladding offers a much higher level of protection against wear, abrasion, and corrosion. The alloys provide tailored resistance profiles for extreme environments like offshore, mining, or food processing. Nickel chrome simply doesn’t offer the same performance, especially under mechanical stress or in chloride-rich conditions.

Resistant to impact and thermal cycling

Nickel chrome cracks under sudden load or temperature swings. Laser-clad coatings absorb and distribute stress. That makes them perfect for dynamic, high-load environments.

Longer service life and reusability

While both nickel chrome plating and laser cladding can be removed and reapplied, laser cladding offers far more precision and flexibility in repair. Nickel chrome requires a uniform coating thickness and offers limited ability to compensate for areas where the base material has been eroded. Localised repairs are difficult and often require stripping and recoating the entire surface.

With laser cladding, you can rebuild individual zones of a worn part to exact specifications. You may even apply thicker layers where corrosion has removed more material. This means you can restore components fully and selectively, without overengineering or scrapping the entire part. It’s a more circular, cost-efficient approach to long-term maintenance.

Cleaner and more sustainable

Laser cladding avoids the hazardous chemicals used in nickel chrome plating. This includes hexavalent chromium which is known for its environmental and health risks. The process produces no harmful waste, uses less material overall, and significantly reduces CO₂ emissions by extending the lifespan of components. As industries move toward greener manufacturing, laser cladding offers a future-proof alternative that aligns with sustainability goals.

Greater design flexibility

Because laser cladding is digitally controlled, you can precisely apply different thicknesses on specific areas of a component. This level of selective reinforcement is not possible with uniform coatings like nickel chrome, and allows for smarter, leaner engineering.

Industries benefiting from laser cladding

Laser cladding has proven itself across a wide range of sectors:

- Offshore & Maritime: long-term resistance against seawater corrosion

- Mining & Heavy machinery: rebuilding wear surfaces on large components

- Steel industry: protecting rollers, tools, and high-stress contact parts

- Infrastructure: restoring bridge and water lock components to original strength

- Food processing: hygienic, durable coatings for contact parts

Why Topclad understands Nickel Chrome

Topclad’s roots lie in Plating Solutions BV, a company that specialized in industrial nickel and chrome electroplating. That background gave us in-depth knowledge of traditional surface treatments and their performance in the field.

But over time, we saw the limitations of nickel chrome: coatings that cracked under stress, insufficient corrosion protection in harsh environments, and a process with serious environmental drawbacks. That’s why we made a conscious shift to laser cladding.

Because we understand nickel chrome so well, we know exactly where it falls short and how to do better. Our engineered laser-clad layers are built to outperform, and they’re tailored to the real-world demands our customers face.

We are Topclad

Topclad is Europe’s leading manufacturer of innovative laser clad layers, based in Lelystad, the Netherlands. We specialize in developing and applying laser clad layers for the most demanding industries, including oil & gas, offshore, dredging, mining, bridges & water locks, steel manufacturing, and food processing.

Our mission is to provide components with superior protection against wear, corrosion, and impact, resulting in significantly improved reliability and uptime of capital-intensive equipment. With over 16 years of experience, a steadfast commitment to quality, and a proven track record of over 15,000 laser cladded components, we deliver solutions that enhance the performance and longevity of your critical machinery.

Why Topclad?

- Over 16 years laser cladding experience with over 15.000 cladded components

- More than 10 in-house developed laser clad layers

- Commitment to quality

- Expertise in comprehensive repairs

- 24.000 mm clad length capacity and 2.200 clad diameter capacity

- Chromium-6-free solutions