An improved Cylinder Integrated Measuring System (CIMS)

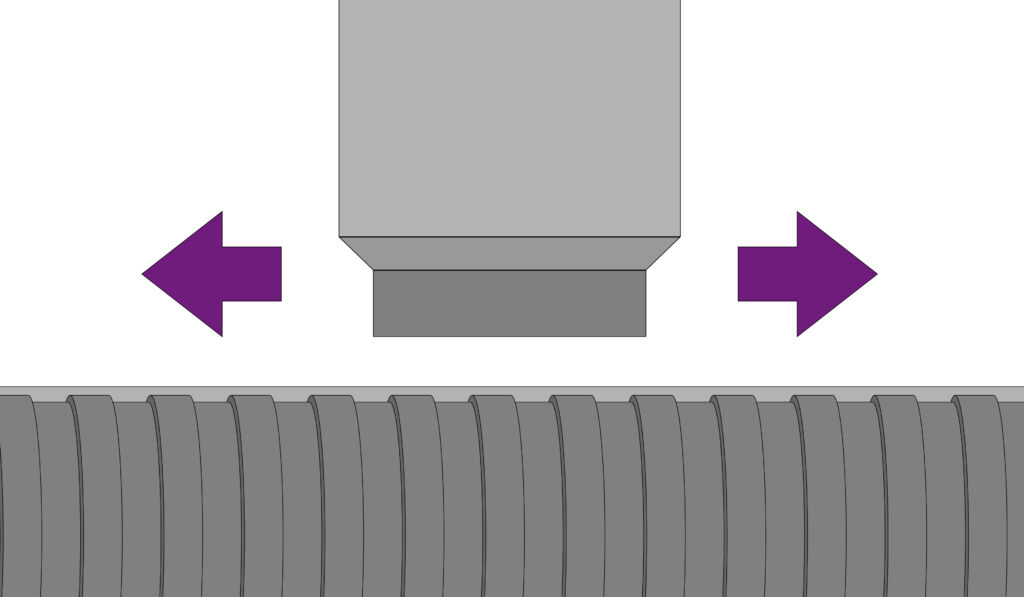

The Topclad Length Measurement System is an improved version of the commonly used Cylinder Integrated Measuring System (CIMS), designed for hydraulic cylinders up to 24,000mm in length. The system works by utilizing a sensor that detects small, interrupted magnetic fields along the cylinder rod. These magnetic fields are positioned at fixed distances over the entire length of the rod. As the rod moves along the sensor, the sensor detects two pulses—one at the beginning of the magnetic field and one at the end. The distance between two magnetic fields remains constant across the rod, ensuring precise measurement. Each pulse sequence (1/0 or 0/1) represents a predefined stroke length, and the cumulative number of signals determines the exact position of the cylinder rod.

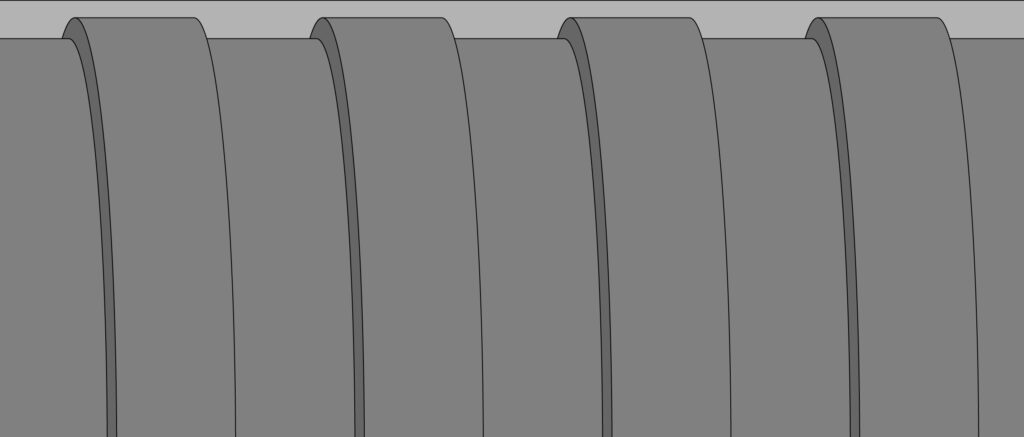

To maintain a smooth surface on the rod, essential for its function, grooves in the magnetic steel rod are filled with a non-magnetic material through laser cladding. Simultaneously, the entire rod is coated with a laser-clad layer, enhancing its resistance to corrosion and wear. This combination of precise measurement technology and advanced cladding provides unmatched performance and durability in demanding environments.

The sensor is a standard device, produced by several manufacturers. TopClad uses the Lenord+Bauer Gel 2478 for testing. This device is executed with two signal pattern functionalities, to be used on pitches of 4mm. In this way, a signal is generated each 1mm instead of a signal per 2 mm stroke length.

The accuracy of measuring can be further increased by applying more sensors, positioned on e.g. 90 degrees from the first one and phase shifted related to the first one.

Technical Specifications & Advantages

| Specifications | Explanation |

|---|---|

| Electronic system compatibility | To be connected to all types of electronic (customized) devices and systems |

| Micro hardness | 310-2700HV, depending on the cladding type |

| Bonding strength | Intermetallic bonding (infinite strength) |

| Versatility | No length restrictions, suitable for various components |

| Porosity | 0% |

| Laser clad layers | Compatible with all Quarite and Tardisphere laser clad layers |

| Calibration | No calibration needed |

| Lifespan & serviceability | Long lifespan and easy serviceability, from outside the oil compartment |

| Costs | Highly cost-effective with high-quality laser cladding |

| Versatility | No length restrictions, suitable for various components |