About us

Today Prepared for Tomorrow

At Topclad, we believe in preparing for the challenges of tomorrow, today. With over 40

years of experience in surface treatment technologies and more than a decade of

expertise in laser cladding, we are committed to providing cutting-edge solutions that

enhance the durability, performance, and reliability of critical industrial components

Core Values

- Innovation: We lead the way in laser cladding, constantly innovating to ensure our customers receive the most advanced protection for their equipment.

- Partnership: We work closely with our customers, understanding their needs and delivering customized solutions that go beyond expectations.

- Quality: Our commitment to quality drives everything we do, from stringent laboratory testing to tailored precision production.

- Sustainability: By offering laser cladding as an environmentally friendly alternative to traditional methods, we reduce waste and extend the lifespan of equipment.

Why choose Topclad

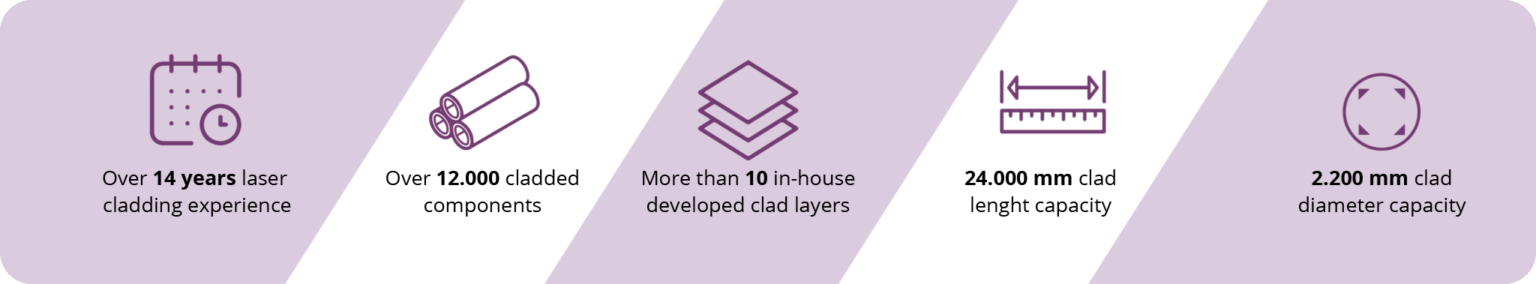

- Proven track record: Since adopting laser cladding in 2012, we have successfully protected over 12,000 components across various sectors, including offshore, marine, dredging, and oil & gas.

- Tailored solutions: Whether it’s restoring worn components or enhancing new ones, our 10+ inhouse laser clad layers are customized for your specific needs, exceeding market standards and other surface treatment methods such as Inconel625 and even other laserclad layers.

- Complex repair jobs: Severely damaged components can be restored within a short timeframe, applying thin or thick layers, and even mixes of different kind of layers.

- State-of-the-art technology: Our advanced laser cladding facilities are equipped with cutting-edge machinery, designed for high precision and capable of handling large-scale components. We are able to process components up to 24,000 mm in length and 2,200 mm in diameter.

Expertise & Solutions

- Hydraulic cylinder rods: Up to 24,000 mm in length, providing superior wear and corrosion protection.

- Drive shafts & bearings: Engineered for high-impact applications like ship propulsion, using our Tardisphere layer.

- Processing drums: Up to 2,200 mm in diameter for the food and paper industries.

- Industry rollers: Heat- and wear resistant rollers up to 950°C

Meet the team

Behind every successful project at Topclad is a dedicated team. With decades of combined experience, our team is passionate about delivering excellence. Recently, Topclad has transitioned to the second generation of ownership and leadership, with Axel Jansen taking over as both owner and Managing Director. This transition ensures that the company’s knowledge, experience, and passion continues to thrive. The new leadership maintains the core values and expertise that have driven Topclad for over 40 years, allowing our customers to continue benefiting from the highest standards in surface treatment and laser cladding technology

Customers

At Topclad, we are committed to delivering outstanding results and ensuring customer satisfaction. We specialize in laser cladding, focusing our efforts to develop expertise and provide unique solutions tailored to specific needs. By maintaining close contact with our customers, we ensure each solution is optimally aligned with their requirements. Our experience allows us to deliver these specialized solutions quickly and efficiently, underpinned by a commitment to quality and innovation that has proven effective across various applications.

Topclad’s history

Topclad originated from the merger of several galvanic companies and initially operated under the name Plating Solutions. With more than 40 years of expertise, Topclad transitioned from traditional galvanic methods to innovative laser cladding. In 2012, we adopted laser cladding as our primary technology, revolutionizing the way surface treatments are applied to industrial components.

Ready to talk

with us?

Topclad Laser Cladding is the leading manufacturer of innovative laser clad layers in Europe. Based in Lelystad, the Netherlands, Topclad Laser Cladding develops and applies laser clad layers for the most demanding industries including oil, gas, sustainable energy, offshore, dredging, mining, bridges and water locks, steel manufacturing and food processing.

"*" geeft vereiste velden aan