Technically, it offers exceptional ductility, allowing treated components to endure significant stresses such as impacts and thermal cycling without cracking. This process also achieves superior metallurgical bonding with the substrate, enhancing wear and corrosion resistance, crucial for extending the service life of critical equipment.

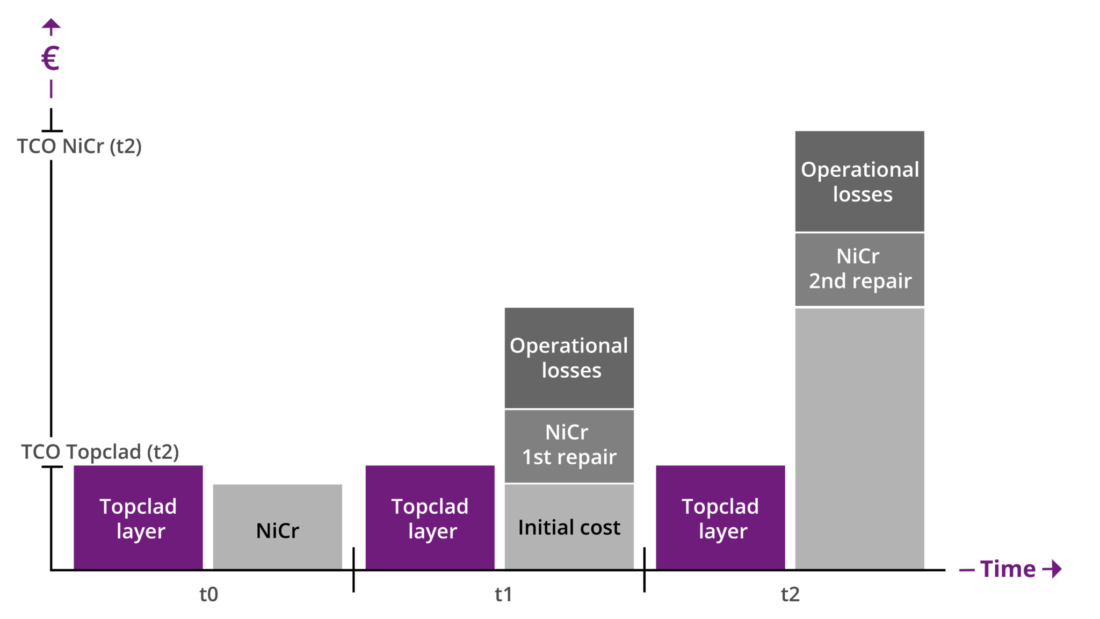

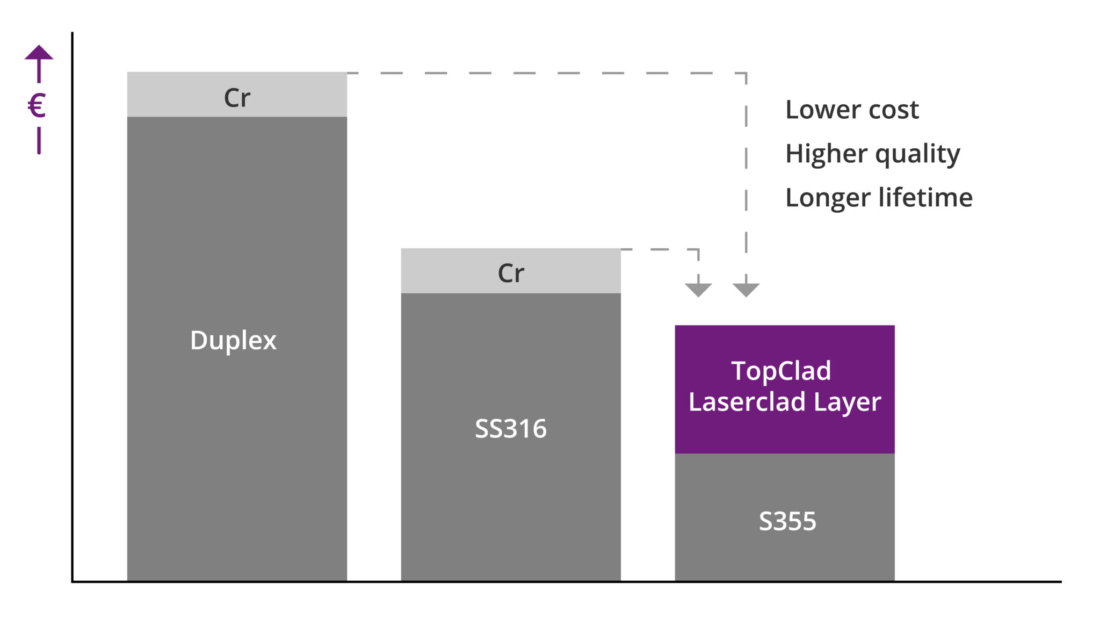

Economically, laser cladding can significantly reduce the total cost of ownership by minimizing maintenance needs and prolonging equipment durability.

Environmentally, it stands out by reducing waste and energy consumption compared to traditional methods, aligning with sustainable manufacturing practices by using fewer hazardous materials. And it eliminates the use of Chromium-6.

Technical advantages

Laser cladding offers numerous benefits, positioning it as a superior choice for various industrial applications. We distinguish these advantages into several key categories:

- Superior Coating Quality

Laser cladding prevents failures due to corrosion, external impacts, bending, or thermal shocks, thanks to intermetallic bonding, high ductility and no porosity (see below). - Excellent repair possibilities

Laser cladding enables cost-efficient and rapid repairs without compromising on quality, thereby extending the lifespan of components and enhancing equipment uptime. - Extended component lifetime

Components treated with laser cladding have a significantly longer service life due to enhanced wear resistance and surface hardness. - Versatility in material choices

Laser cladding can be applied to a wide range of materials, including carbon steels, stainless steels, duplex steel, nickel-based alloys, and more. This versatility allows for customized solutions tailored to specific industrial requirements. - Reduced heat-affected zone

The localized heating of laser cladding minimizes the heat-affected zone (HAZ) around the deposition area. This preservation of the base material’s mechanical properties and microstructure is crucial for maintaining overall component integrity. - High precision and control

Laser cladding offers unmatched precision in material deposition, ensuring exact coating thickness and placement. This precise control minimizes material waste and reduces post-processing requirements.

Intermetallic Bonding

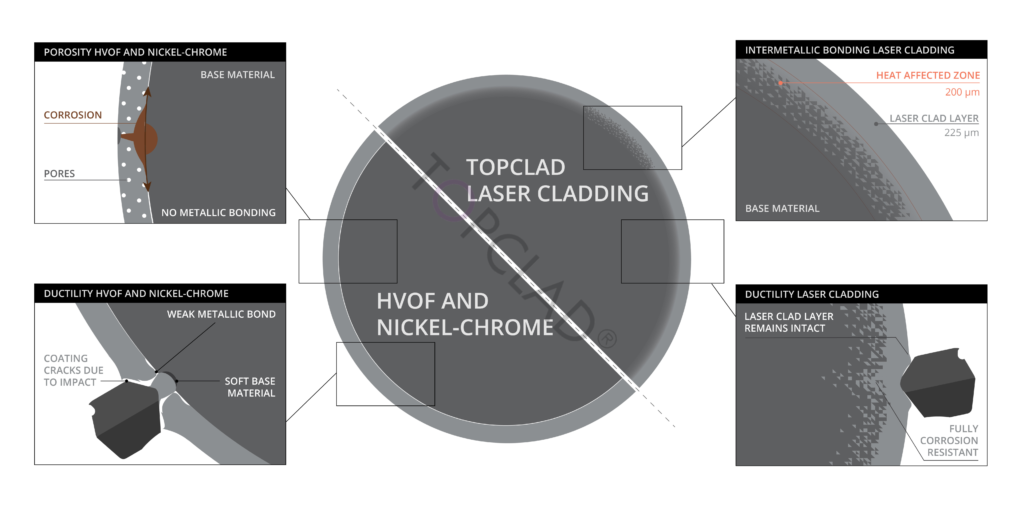

During laser cladding, an alloy is melted with the base material, creating an intermetallic bond between the two. This process inherently prevents subcorrosion between the laser cladded layer and the base material. In contrast, HVOF and NiCr coatings are not melted but mechanically bonded. These coatings can hold pores and develop cracks, allowing substances like seawater to penetrate the coating, corrode the base material, and eventually push off the coating from the inside out.

No Porosity

Laser clad layers have 0% porosity, forming an impermeable barrier that prevents corrosive fluids from reaching the base material. This feature significantly enhances protection against subcorrosion compared to traditional coatings.

High Ductility

Laser clad layers exhibit exceptional ductility, allowing them to absorb material stress from impacts, bending, and thermal cycling without cracking. This property is critical for components subjected to harsh operational environments as it absorbs high material stress and, consequently, avoids cracking. HVOF and NiCr coatings are not ductile at all; bending, external impacts and thermal shocks will inevitable result in cracking. This high ductility, combined with the intermetallic bonding, prevents heavy damage due to external impacts (e.g. rocks or tools), bending (e.g. long thin rods) and thermal shocks (e.g. steel production process).

Overhaul of heavily damaged products

Severely damaged components can be restored by applying a laser clad layer several millimeters thick. This process avoids the need for costly replacements and lengthy remanufacturing processes. This saves time and resources as the critical parts can be overhauled in days instead of weeks.

Repairability of damaged threads

Laser cladding effectively repairs heavily damaged thread by removing and re-cladding material, resulting in thread with higher tensile strength than standard carbon steel. Cladded thread prevents corrosion and hence ensures smooth disassembly of threated counterparts such as piston rod eyes.

On-site repair capability

Minor damages can be repaired on-site using standard TIG welding equipment, eliminating the need for component disassembly and minimizing downtime.

Environmental advantages

We help you achieve your environmental goals without compromising on performance and reliability. By using our laser cladding technology, your components last longer, waste is minimized, and the use of hazardous substances is reduced, significantly lessening the environmental impact of your operations. At Topclad, sustainability is at the heart of everything we do, ensuring your business remains efficient and eco-friendly.

By choosing laser cladding, you contribute to environmental conservation while achieving superior performance and durability for your industrial applications.

Waste reduction

Minimal waste generation compared to traditional coating methods, thanks to precise material application and the ability to refurbish components.

Resource conservation

Extends the life of components, reducing the need for new raw materials and conserving natural resources.

Energy efficiency

Topclad’s laser cladding technology uses localized heating to significantly reduce energy consumption compared to traditional nickel-chrome plating (NiCr). This focused application of energy enhances efficiency and lowers the carbon footprint, providing a greener alternative to conventional coating methods.