Topclad Laser Cladding

Topclad Laser Cladding is the leading manufacturer of innovative laser clad layers in Europe. Based in Lelystad, the Netherlands, Topclad Laser Cladding develops and applies laser clad layers for the most demanding industries including oil, gas, sustainable energy, offshore, dredging, mining, bridges and water locks, steel manufacturing and food processing.

Our goal: ”to provide components with a superior protection against wear, corrosion and impact with a highly improved reliability and uptime of capital intensive equipment as a result.”

Applications

Topclad laser clad layers are being used for a wide range of applications including hydraulic cylinder piston rods, ship propeller shafts, bearings, rollers and drums. New components are upfront provided with superior surface properties and damaged components are repaired while adding optimized protection.

Topclad is able to clad components up to 2.200 mm in diameter and 24.000mm in length.

Markets

Topclad Laser Clad Layers

Customers

Latest news & projects

-

Topclad® Tardisphere® for standard and custom made slide bearings

Topclad® Tardisphere® laserclad coating on slide bearings for propellor shafts and machine parts Topclad is the innovation center for laserclad applications. Tardisphere is one of our laserclad products which performs excellent against wear. Since 2012, Tardisphere is used on cylinder rods with extreme high side load. Research at Topclad for the last decade, found that

-

The ultimate solution for repair of corroded cylinder rods

Laser cladding in 2020 Repair of corroded cylinder rods Since 2012, Topclad provides hydraulic cylinder rods with laserclad coatings against corrosion and wear. Topclad lasercladding is the most innovative and durable alternative for galvanic nickel chrome and HVOF coatings. Very reliable, long lifetime and very low “cost of ownership”. Topclad gets weekly requests to repair cylinder rods, galvanic or HVOF coated, that

-

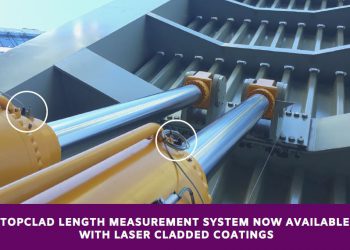

Topclad Length Measuring System (TLMS)

Topclad length measuring system (TLMS) Now available with laser cladded coatings Hydraulic cylinders are used in many different applications, where controlled forces and controlled stroke lengths are important functionalities, in addition to corrosion and wear resistance properties that are important for a long lifetime. TopClad TLMS has the capabilities to offer all of these functionalities